| |

|

|

Water

tightness Ensured…

To ensure our Dome™ covers are completely waterproof,

all seams in our fabric materials are heat welded and

all cover components (i.e., main cover, end and front

panels) are joined with storm flaps to provide additional

moisture protection. Also, all access door panels are

equipped with heavy-duty nylon zippers that will not break

in heavy winds or in extreme cold conditions to further

ensure water tightness.

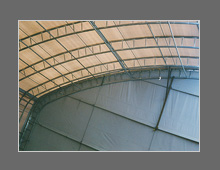

Sturdy and Simple Connection

Design…

The cover of a Dome™ Shelter is secured and tightened

to the base frame using ratchet straps and turnbuckles.

The combination of steel inserts and ratchet straps are

used to fasten the main cover to the base frame. The advantage

of using steel inserts is to evenly distribute tension

along the length of the shelter and eliminate wrinkles.

Front end panels and are fastened to the end hoops using

high strength no-stretch, woven cords. All cords are threaded

through rustproof brass grommets, punched through automotive

grade seat belt fabric (i.e., material stress bands with

a strain capacity of 5000 lbs). This makes installing

the cover easy and greatly enhances the life and appearance

of the cover by ensuring it is tight and evenly stretched.

Our standard steel frame consists of structural steel

arches and purlins to reinforce and brace the frame. For

easy installation, factory welded metal inserts connect

all steel tubing in the main frame and purlins are held

in place with brackets and self-tapping screws.

|

|

|

|

|

|